For a year now, the world is battling a wide-spread pandemic of COVID-19 diseases. This highly infectious respiratory disease caused almost two million deaths worldwide, and unfortunately, it’s far from over.

Although the vaccine is already here, the time it will take to vaccinate most of the world’s population is very long. In the meantime, we need to do everything possible to protect ourselves and our families from being infected. This is where ACTIVE SHIELD comes into play.

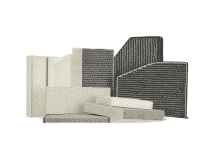

Our unique coating technology was developed by Bar Ilan University in Israel to solve the problem of infections in hospitals by treating patient linens and doctors’ scrubs, making them antiviral and antibacterial. After researching the technology, we managed to customize it to treat filtration media used to produce indoor air and cabin filters.

Our patented technology utilizes sono-chemical assistant treatment to coat filtration media with metal-oxide, granting it antiviral and antibacterial properties. “This technology is greener and safer than any other available today,” says Itsik Levy A.L. GROUP’s R&D Manager. ” We do not use any harmful chemical binders in our impregnation process. We also don’t add any metal fibers.”

ACTIVE SHIELD filters disrupt harmful organisms’ protective layers and interfere with their vital processes, leaving them harmless and unable to multiply. We tested our ACTIVE SHIELD under ISO 18184:2019 standard against SARS COV 2 in one of China’s leading laboratories. It came through with flying colors showing over 99% of antiviral activity and over 2 log reduction in viral load.

Extensive medical tests under ISO 20743 were carried out to evaluate ACTIVE SHIELD’s antibacterial efficacy against E.coli and S.aureus. The results demonstrate an excellent antibacterial activity of 3 log reduction in bacteria growth.

Another big advantage of this technology is that it can be combined with additional layers of the cabin filter, creating a multifunctional filter with carbon media, bio protection layers, HEPA media, etc. “We tried our sono-chemistry assistant treatment on different types of filtration media used in A.L. GROUP to produce air cabin filters and found it to be excellent in impregnating all of them with metal oxide,” says Avi Pollak, our VP Development & Engineering. “This process can be used with carbon and HEPA media and can be combined with additional bio-functional layers to create a multifunctional filter.”

We plan to implement ACTIVE SHIELD in our range of automotive filters on all our markets, including EMEA, USA and, Asia Pacific. “We offer our customers the flexibility to choose which cabin filter they want, a regular pollen filter, a carbon filter, or the ACTIVE SHIELD.” Says our VP of Sales & Marketing – Asaf Shafrir. “In addition to our automotive customers, we already have multiple interests from the in-door filtration market. I believe that soon we will see ACTIVE SHIELD implemented in residential homes, hospitals, hotels, and of course, public transportation.”

As the importance of clean air becomes more and more evident, solutions such as ACTIVE SHIELD are crucial to putting the pandemic behind us and getting back to our normal lives.

To find out more please visit: https://active-shield.algroup.com